Understanding the differences between primary-variable and primary-secondary boiler designs can mean having an efficient, long-lasting hydronics system and one that can be prone to boiler and heat exchanger inefficiency, leaks, damage, and other operational challenges.

Primary-Secondary Boiler Systems: A Focus on the Boiler

These systems are typically chosen when flow rates vary and typically include 2-way valves. Key factors:

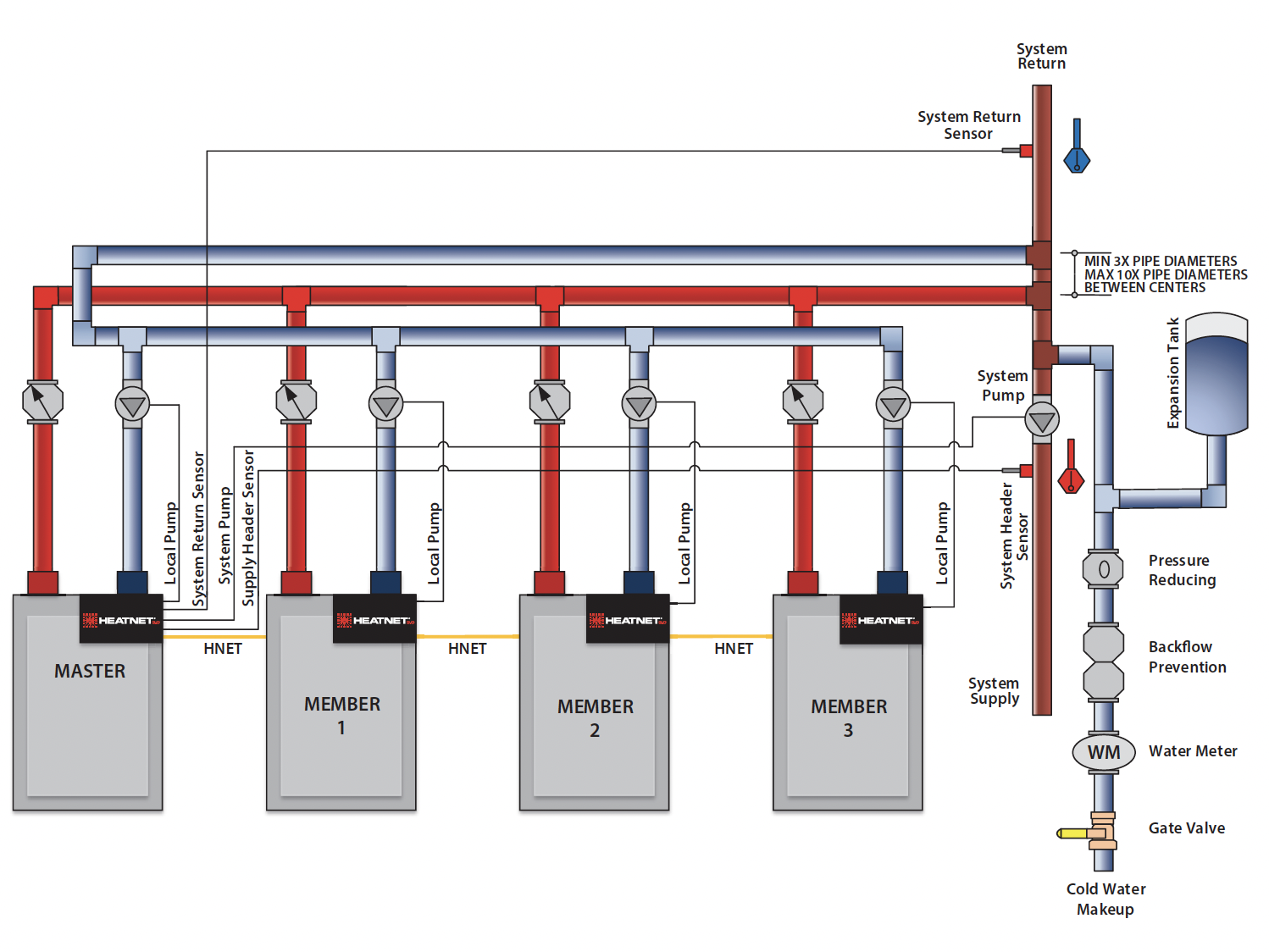

- Flow Rate: primary-secondary designs are useful in situations where boilers can’t handle lower flow rates provided by system two-way valves; the independent primary pump can pump at any flow while the secondary pump modulates based on flow changes

- Delta T: if the system’s temperature difference (delta T) doesn’t match the boiler’s capability, primary-secondary piping becomes necessary; if the system has a 30° delta T at design but the boiler can only manage a 20° temperature difference, the boiler manufacturer will require primary secondary piping to operate without cycling and exposing the heat exchanger and boiler to large temperature differences

Variable Primary Systems: Prioritizing the System

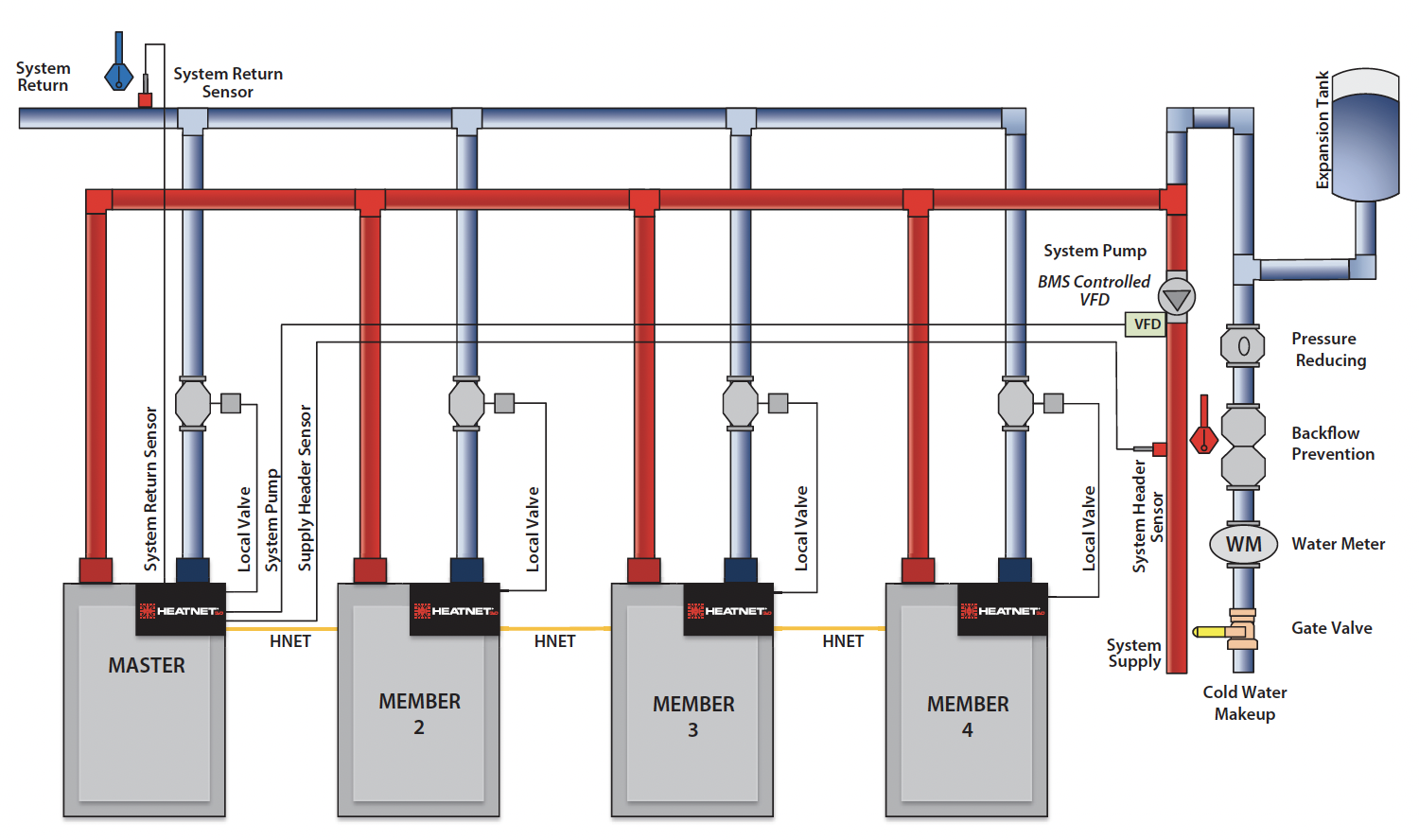

When focused on the system’s needs rather than the boiler’s limitations, variable primary systems are chosen. These systems are typically chosen in an attempt to reduce costs and typically include bypass valves. Key factors:

- Flow Rate: if the boiler can match the system turning down to a low percentage of the design flow rate, then a variable-primary system is preferable with a common piping system

- Delta T: if the system’s temperature difference (delta T) matches the boiler’s capability, then primary-variable works well

Primary-Secondary: Today’s Choice

While both designs have their merits, understanding the system’s needs and the abilities of the chosen boiler are critical in determining the best fit. For many situations, a primary-secondary design offers more benefits:

- Optimized Flow & Delta T: a primary-secondary design provides more consistent flow for the boiler despite system fluctuations; this is crucial for maintaining boiler efficiency and consistent temperature, the latter of which reduces boiler cycling, metal fatigue, and leaks

- Adaptation to Modern Boiler Design: old boilers were built like battleships, so they had higher tolerances and could be switched on and forgotten; boilers today are smaller, more efficient, and have less metal and material; with less water and a reduced amount of materials, they’re less resilient to inconsistencies and cannot be pushed beyond their limits; a primary-secondary system ensures they operate within their safe limits

- System Damage: if boilers and heat exchangers operate beyond their optimal GPM and temperature ranges, the chances of damage and leaks increase exponentially due to temperature fluctuations, expansion and contraction, and metal fatigue; the primary-secondary design acts as a safety net, maintaining the boiler within its safe operational parameters

Case Study: Conversion from Variable Primary to Primary-Secondary

A luxury apartment development in Chicago recently faced a significant heating challenge post-construction. Their dual 6,000,000 BTU boilers operated in a variable primary system, often cycled on and off due to a mismatch between boiler capacity and building load. This discrepancy led to rapid wear and heat exchanger failures in both buildings.

After several months of collaboration among multiple expert teams, including Maddock Industries and Heatmasters Mechanical, a primary-secondary redesign was implemented. The reconfigured system transformed the boilers by integrating a Spirotherm Quad hydraulic air and dirt separator, enhancing efficiency. This strategic overhaul improved heating consistency, saved the owners significant potential replacement costs, and dramatically reduced tenant complaints. Read the case study >

Optimized System Design

To learn more about the right boiler design and other components for your system, speak to one of our hydronics experts.