In an ideal world, a hydronic system operates quietly in the background, heating and cooling a building without drawing attention to itself. But in reality, noise and vibration are two of the most common and frustrating issues facility managers and mechanical contractors face.

From the sudden jolt of water hammer to the low hum of a vibrating pump, these sounds aren’t just irritating — they’re symptoms of deeper issues that can reduce system efficiency, increase maintenance costs, and shorten equipment lifespan.

So, where do these issues originate, and how do you address them?

The Usual Suspects

Most noise and vibration problems in hydronic systems can be traced back to a few key culprits. For example, air trapped in the system creates the familiar gurgling or knocking sound. At the same time, improperly sized piping can cause turbulent, high-velocity flow that amplifies noise throughout the building. Loose fittings, pump cavitation, and sudden flow stoppages—also known as water hammer—all contribute to additional unwanted acoustics.

And then there’s the equipment itself. Pumps, chillers, cooling towers, and fans naturally produce vibration during operation. Without proper isolation, those vibrations can transfer into the piping system, structural components, and even the walls and ceilings of occupied spaces.

The Ripple Effects of a Noisy System

While these noises might seem like minor annoyances, they can have major consequences. Over time, excessive vibration can lead to fatigue and failure in piping and mechanical components. Occupant complaints can lead to downtime or costly retrofits, especially in environments like hospitals, schools, and office buildings where quiet operation is critical. In commercial settings, there’s also the risk of running afoul of local noise ordinances or failing to meet LEED acoustic performance standards.

Designing for Silence

The good news? Many of these issues can be mitigated or avoided entirely with a smart system design.

Choosing the right pump size and type helps prevent excess noise from over-pressurizing or cavitation. Flexible connectors and vibration isolators (such as spring mounts and inertia bases) are essential for decoupling equipment from the piping system. Pipe hangers and supports should be placed with thermal expansion in mind, and acoustic insulation can help minimize noise in sensitive areas.

One component that often gets overlooked is the expansion tank. When sized and placed correctly, an expansion tank helps manage pressure fluctuations and reduces system stress, keeping everything running more quietly and smoothly.

Air Elimination: The Silent Hero

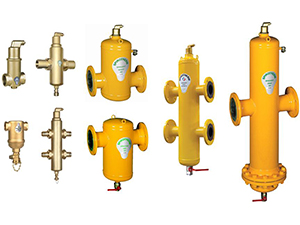

Another major player in reducing noise is air elimination. Air bubbles in a closed-loop system don’t just hinder performance—they’re noisy. That’s why air separators and automatic air vents are critical for modern hydronic systems. Products like Spirotherm’s Spirovent® line remove both air and dirt, improving system efficiency while eliminating many of the sounds associated with poor flow and turbulence.

Keep It Quiet with Routine Maintenance

Even the best-designed system can get loud over time without ongoing attention. That’s why maintenance is key. Routine inspections help catch loose fittings and worn isolation components early. Monitoring pump performance can prevent cavitation and over-pressurization, while regular flushing and balancing help maintain steady flow rates, all of which contribute to quieter, longer-lasting operation.

At Maddock Industries, we carry trusted products that help reduce noise and vibration from the start. That includes Spirotherm’s reliable air and dirt separators and a full line of Vibro-Acoustics components that includes flexible connectors, isolators, and acoustic solutions engineered for commercial systems.

If you’re designing a new system or troubleshooting a noisy one, we’re here to help you find the right solution.